Our piston-, solenoid- and gear-pumps

MPO

solenoid pump

for oil

- compact design

- easy to use and to assemble

- different drive power

- available for explosive-risk environments (ATEX)

- control: either via existing PLC or time control UNI CONTROL

- optional: with function control

- optional: remaining fill level check with solenoid float switch SMM 50

Types

| Outlets | Duty cycle | Max. pressure |

|---|---|---|

| 1 | ED 100% ED 25% ED 15% | 25 bar (24V/230V) 56 bar (24V) 64 bar (230V) |

| 2 | ED 100% ED 25% ED 15% | 13 bar (24V/230V) 32 bar (24V) 44 bar (230V) |

| 3 | ED 100% ED 25% ED 15% | 08 bar (24V/230V) 24 bar (24V) 25 bar (230V) |

| 4 | ED 100% ED 25% ED 15% | 06 bar (24V/230V) 14 bar (24V) 14 bar (230V) |

Technical specifications

| Outlets | 1xG⅛", 2xG⅛" or 1 to 4x Tube fitting Ø 4 mm |

|---|---|

| Delivery rate | 0,03 ml (30 mm³ per stroke and output) |

| Temperature range | -10 °C to +50 °C |

| Lubricating medium | Oil (11 to 1900 cP) |

| Sealing material pump: | FKM |

| Voltage | 24 V DC (230 V AC) |

| Triggering / Resting period | 0,1 sec / 0.25 sec |

| Nominal operating mode | 100 % on-duty (15 % intermittend duty) |

| Tank volume | 200, 500,1000, 2000, 3000, 5000, 9000 ml |

| Type | Volume | Diameter | Height | Ordering no. |

|---|---|---|---|---|

| UNI-grease-cartridge | 460 ml | approx. 115 mm | approx. 150 mm |

Types

| Type | Operating pressure | Wattage | Nominal operation | Ordering no. |

|---|---|---|---|---|

| UNI-MPF 60 f. grease cartridge | 60 bar | 1,3 A | 100% on-time | |

| UNI-MPF 60 f. grease cartridge | 60 bar | 1,3 A | 100% on-time | |

| UNI-MPF 100 f. grease cartridge | 100 bar | 5,0 A | 25% intermittent duty | |

| UNI-MPF 100 f. grease cartridge | 100 bar | 5,0 A | 25% intermittent duty |

Technical description for electrical activation

| Outlet | 1x G⅛" (optional for progressive distributors up to 8 outlets possible) |

|---|---|

| Delivery rate | 0,025 ml / 25 mm³ per stroke |

| Temperature range | +10 °C to +50 °C |

| Pumped medium | Grease (NLGI grade 1 and 2) |

| Material | Stainless steel / Aluminium |

| Sealing material | 1x G⅛" (optional for progressive distributors up to 8 outlets possible) |

| Voltage | 24 V DC |

| Triggering / Resting period | min. 0,25 sec |

EPO

Oil pump and dosing oiler

with tank

For single-line operations combined with oil droppers to supply several lubrication points. Or to supply one lubrication point directly with single-stroke activation (about 7 mm³ per stroke), e.g. a lubricating brush for chain lubrication.

- type EPO 500 to 3000 (1,2 bar)

- thread connection: throttle valve G 1/8

- tank: nickel-plated brass / NBR or FKM

- for light to medium machine oils and chain oils

- pump: brass, stainless steel, FKM

- control: either via existing PLC or time control UNI CONTROL

- optional: remaining fill level check with solenoid float switch SMM 50

| Type | A | B | Ordering no. |

|---|---|---|---|

| EPO 500 | 187 | 84 | |

| EPO 1000 | 213 | 104 | |

| EPO 2000 | 250 | 138 | |

| EPO 3000 | 287 | 155 |

Technical specifications

| Tank size | 500, 1000, 2000, 3000 |

|---|---|

| Ambient temperature | +40° C max. |

| Degree of protection | IP65 with an appliance plug |

| Operating voltage | 24 V 50 Hz 110 V 50/60 Hz 230 V 50 Hz Also 24 V DC with a pulsed signal via PLC or UNICONTROL Other voltages available upon request |

| Wattage | 29 VA |

| Nominal operating mode | 100% on-time |

| Operating pressure | 1,2 bar |

| Delivery rate | approx. 21 cm³/min with 65 cSt oil in continuous operation at 50 Hz, or approx. 7 mm³/stroke With water or aqueous fluids approx. 250 cm³/min |

EPO 5000 / EPO 9000

piston pump

Distribution to several lubrication points takes place via ETR und MTR oil droppers. Combinations with UNI lubricating brushes SPR or SPF or the RSM and RSM-B roller brushes have proved to be successful for chain lubrication. The EPO 5000 and EPO 9000 lubrication units are available with up to 6 installed EET 200 pumps. This enables six lubrication lines to be supplied, separately controlled, from one storage tank.

- aluminum

- thread connection: throttle valve G 1/8

- supplied as ready-to-connect installation units with a pump and oil tank

- pump EET 200 mounted, incl. throttle valve, on aluminum tanks with a capacity of 5 or 9l

- for light to medium machine oils and chain oils

- control: either via existing PLC or time control UNI CONTROL

- optional: remaining fill level check with solenoid float switch SMM 50

| Type | Ordering no. |

|---|---|

| EPO 5000 | |

| EPO 9000 |

Technical specifications

| Tank size | 5000, 9000 |

|---|---|

| Ambient temperature | +40° C max. |

| Degree of protection | IP65 with an appliance plug |

| Operating voltage | 24 V 50 Hz 110 V 50/60 Hz 230 V 50 Hz Also 24 V DC with a pulsed signal via PLC or UNICONTROL Other voltages available upon request |

| Wattage | 29 VA |

| Nominal operating mode | Single strokes or continuous operation with 100% on-time |

| Operating pressure | 1,2 bar |

| Delivery rate | approx. 21 cm³/min (with 65 cSt oil) in continuous operation, or 7 mm³/stroke |

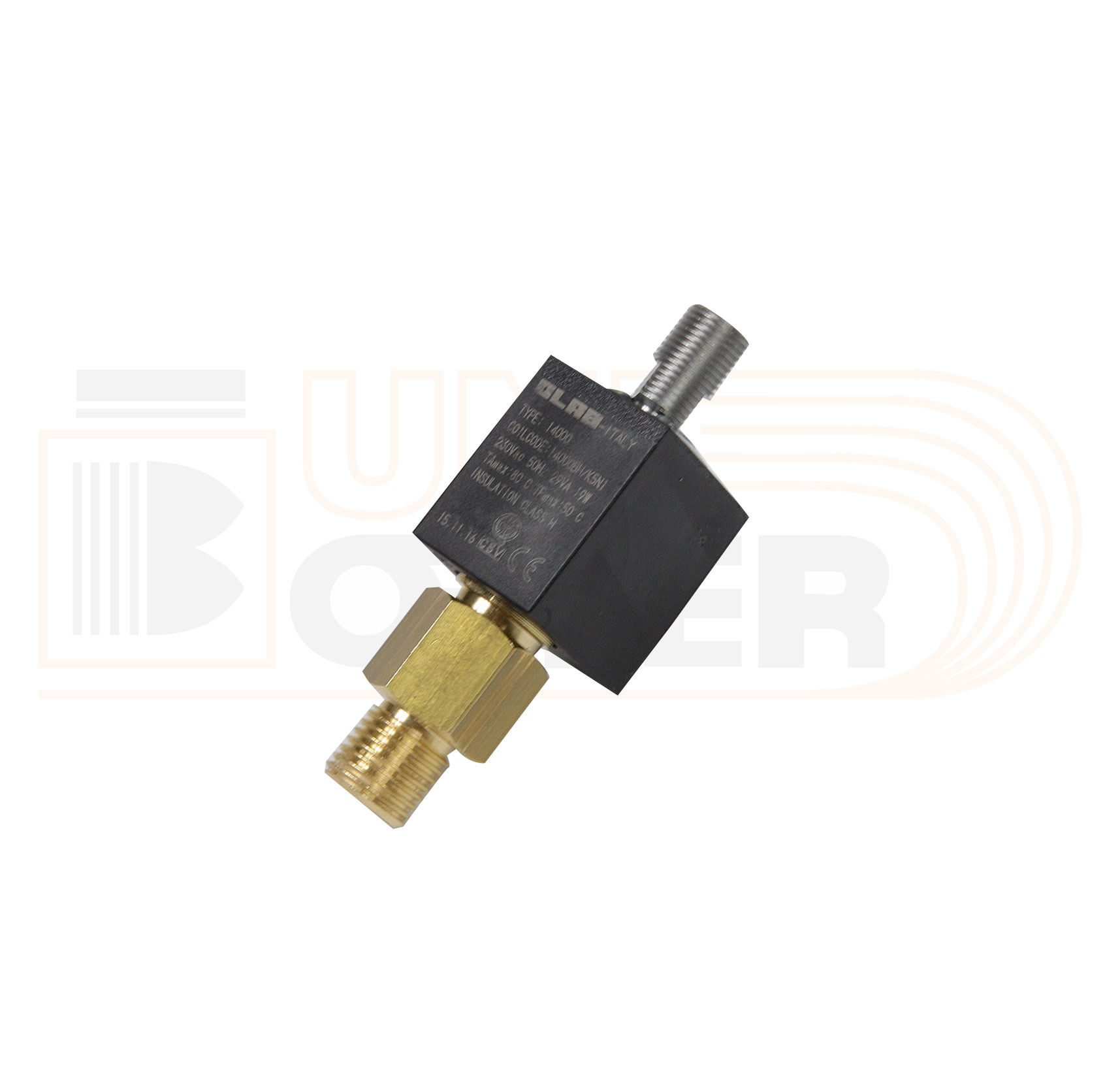

EET 200

oscillating piston pump

- for single-line operation

- max. pressure of 1.2 bar intermittently to a height of up to about 10 m

- brass, stainless steel, Viton (FKM)

- control: either via existing PLC or time control UNI CONTROL

| Type | Ordering no. |

|---|---|

| EET 200 |

Technical specifications

| Ambient temperature | +40° C max. |

|---|---|

| Degree of protection | IP65 with an appliance plug |

| Operating voltage | 24 V 50 Hz 110 V 50/60 Hz 230 V 50 Hz Also 24 V DC with a pulsed signal via PLC or UNICONTROL Other voltages available upon request |

| Wattage | 29 VA |

| Nominal operating mode | Continuous operation with 100% on-time |

| Operating pressure | 1,2 bar |

| Delivery rate | approx. 21 cm³/min with 65 cSt oil in continuous operation at 50 Hz or approx. 7 mm³/stroke With water or aqueous fluids approx. 250 cm³/min |

EET 300

self-priming oscillating piston pump

- max. pressure: 15 bar

- 100% duty cycle

- Connections: G ⅜" inner thread

- control: either via existing PLC or time control UNI CONTROL

| Type | Voltage | Wattage | Ordering no. |

|---|---|---|---|

| EET 300 /6 - V10 | 230 V 50 Hz | 60 W | |

| EET 300 /6 - V10 | 110 V 50 Hz | 70 W | |

| EET 300 /15 - V8 | 230V 50 Hz | 60 W |

Technical specifications

| Ambient temperature | +40° C max. |

|---|---|

| Degree of protection | IP65 with an appliance plug |

| Operating voltage | 230 V 50 Hz / 110 V 50 Hz |

| Wattage | max. 70 VA |

| Nominal operating mode | Continuous operation with 100% on-time |

| Operating pressure | up to 15 bar |

| Delivery rate | approx. 95 l/h at 15bar; approx. 230 l/h at 6bar |

FT / FM

self-priming monoblock gear pumps

- the grey cast iron version can be equipped with 2 different motor outputs

- FT or FTG: max. pressure: 5 bar

- FM or FMG: max. pressure: 10 bar

- pumps FMZ (bronze) or FMX (stainless steel): supplied categorically for pressures of up to 10 bar

- for low and medium viscosities

- max. temperature: +200 °C

- max. temperature of the standard version: +90 °C

- optional: with an internal bypass valve

- optional: available for explosive-risk environments (ATEX)

Main areas of application:

- The delivery and spraying of heating oil or delivery of heavy oil for burners with pneumatic spraying devices.

- As a feed pump for delivering heating oil or heavy oil to burner pumps with a mechanical spraying device.

- Delivery of thermal oil into temperature control devices.

- Delivery of concrete additives.

- Delivery of oil for the lubrication cycle in industrial facilities.

- Lubrication of industrial compressors (oil, oil with ammonia and oil with CFCs).

- Lubrication of large gearboxes.

- Cooling of large electrical transformers.

- Delivery of oil, heavy oil or diesel into dosing systems with a tank, pump, flow meter and dosing gun.

- Delivery of dyes for the textile and vehicle industries.

- Delivery of water emulsions.

- Delivery of fluids in the food industry.

Are you interested in our

piston-, solenoid & gear-pumps?

If so, please arrange a consultation meeting now, with no obligation on your part. If you have any questions, our team will be pleased to assist you and explain all of the possible applications. Simply phone +49 7907 942 92 0, send an e-mail to info@unioeler.de or use the contact form.