Our progressive distributors

Progressive distributors

A module for centralized lubrication systems and high-performance lubricators. The incoming lubricant is branched off into between 2 and 8 outlets and is distributed by force and uniformly in synchronization with the piston movements.

A piston stroke delivers 0.09 cm³ and 0.2 cm³ of lubricant per outlet. Alternative electronic monitoring. The pistons in the distributor move consecutively in repeating cycles under the pressure of the incoming lubricant. Not until a piston has completed its full stroke can the next one start its run. It does not matter whether the lubricant delivery is continuous or intermittent. With this mode of operation, no lubrication point can be left out. All line lengths receive the same amount of grease.

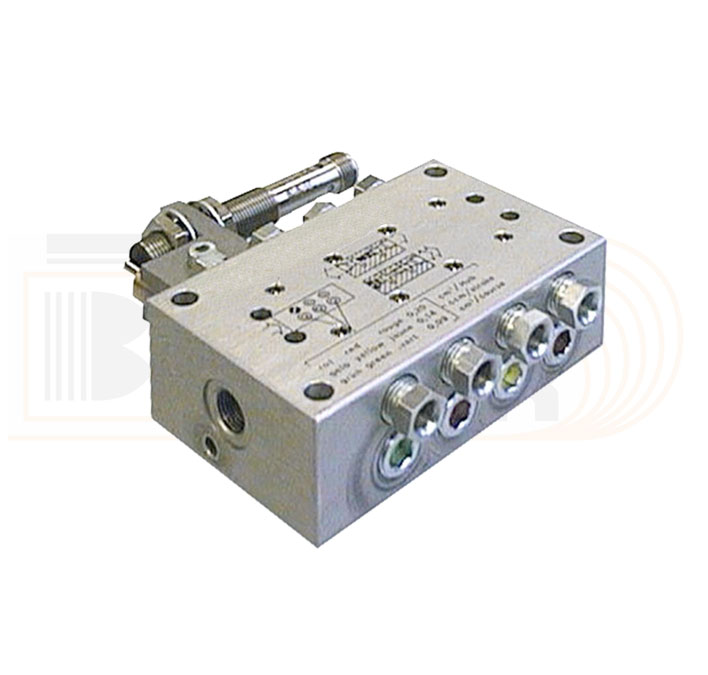

VPB-B

progressive distributor

Der WOERNER progressive distributor VPB-B is used in progressive mode based central lubrication systems.

- Number of outlets: 6-20

- Number increasable in steps of 2

- Medium: oil or grease

- Dosing volume (in cm³ per cycle: 0,09 - 0,2

- Permissible operating pressure: 150 bar

- Material: aluminium

- Accurate proportioning volumes

- Three different proportioning volumes: selectable in accordance with the lubricant volume required.

- Extremely long service life due to refined sliding surfaces

- Easy combination of opposing outlets

- Various options for monitoring

Technical data:

| Input | G ⅛ |

|---|---|

| Outlets 6-20 | M10x1. Recommended: hose connections with check valve |

| Operating temperature | -20 °C to +80 °C |

| Piston stroke | see table |

| Delivered medium | Oil / grease (oil from 140 cP or grease up to NLGI-class 2) |

| Operating pressure | 150 bar max. |

Function check:

- without (0)*

- with monitoring (S)*

- Reedcontact with cable (RK)*

- Reedcontact with plug (RS)*

| Type* | Outlets* | Proportioning vol. / output* | Article No. |

|---|---|---|---|

| VPB-B 6 | 6 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-B 8 | 8 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-B 10 | 10 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-B 12 | 12 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-B 14 | 14 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-B 16 | 16 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-B 18 | 18 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-B 20 | 20 | 0,09 cm³/cycle or 0,2 cm³/cycle |

For further details download the PDF.

* Please specify when ordering.

VPB-G

progressive distributor

Der WOERNER progressive distributor VPB-G is used in progressive mode based central lubrication systems.

- Number of outlets: 2-8

- Medium: oil or grease

- Dosing volume (in cm³ per cycle: 0,09 - 0,2

- Permissible operating pressure: 150 bar

- Material: aluminium

- Accurate proportioning volumes

- Three different proportioning volumes: selectable in accordance with the lubricant volume required.

- Extremely long service life due to refined sliding surfaces

- Easy combination of opposing outlets

- Various options for monitoring

Technical data:

| Input | G ⅛ |

|---|---|

| Outlets 2-8 | M10x1. Recommended: hose connections with check valve |

| Operating temperature | -20 °C to +80 °C |

| Piston stroke | see table |

| Delivered medium | Oil / grease (oil from 140 cP or grease up to NLGI-class 2) |

| Operating pressure | 150 bar max. |

Function check:

- without (0)*

- with monitoring (S)*

- Reedcontact with cable (RK)*

- Reedcontact with plug (RS)*

| Type* | Outlets* | Proportioning vol. / output* | Article No. |

|---|---|---|---|

| VPB-G 2 | 2 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-G 3 | 3 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-G 4 | 4 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-G 5 | 5 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-G 6 | 6 (Standard) | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-G 7 | 7 | 0,09 cm³/cycle or 0,2 cm³/cycle | |

| VPB-G 8 | 8 (Standard) | 0,09 cm³/cycle or 0,2 cm³/cycle |

Standard: 6 and 8 outlets.

Custumized models: 2, 3, 4, 5, 7 outlets.

For further details download the PDF.

* Please specify when ordering.

Are you interested in our

our progressive distributors?

If so, please arrange a consultation meeting now, with no obligation on your part. If you have any questions, our team will be pleased to assist you and explain all of the possible applications. Simply phone +49 7907 942 92 0, send an e-mail to info@unioeler.de or use the contact form.