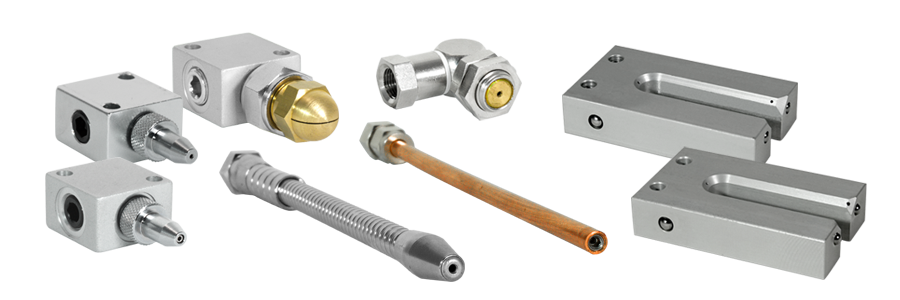

Our nozzles

Copper nozzles

Description:

Flexibly usable round-jet nozzle. An easily malleable copper pipe for ideal adjustment of the spray distance and spray angle. Dimensionally stable even when used on vibrating applications. Individual lengths can be easily implemented on request.

Preferred installation:

A nozzle holder on a magnetic foot or fixed by means of a mounting block.

| Designation | Item no. |

|---|---|

| Cu nozzle pipe 100 mm | 30 001 26 00 |

| Cu nozzle pipe 200 mm | 30 001 25 00 |

| Cu nozzle pipe 300 mm | 30 001 26 30 |

| Cu nozzle pipe 500 mm | 30 001 26 50 |

Metal joint nozzle

Description:

Flexibly usable round-jet nozzle. An easily and quickly malleable, metal-jointed nozzle for ideal adjustment of the spray distance and spray angle, especially in constantly changing operating conditions.

Preferred installation:

A nozzle holder on a magnetic foot or fixed by means of a mounting block.

| Designation | Article no. |

|---|---|

| Metal joint nozzle 200 mm | 90 30 01 02 200 00 |

| metal joint nozzle 250 mm | 90 30 01 02 250 00 |

| metal joint nozzle 320 mm | 90 30 01 02 320 00 |

Accelerator nozzle

Description:

A universally usable round-jet nozzle. By adjusting the spray air and the amount of medium passing through the pump, a very exact and reproducible spray pattern can be set by means of this nozzle. Even with little spray air, output of the cooling/lubricating medium in a homogeneous 'droplet-air mixture' is possible while avoiding the unwanted formation of mist. For spray points that are at a particularly low level relatively to the pump, the accelerator nozzle should be used with an integrated check valve (opening pressure approx. 0.4 bar) to prevent the line from running empty.

Preferred installation:

Usable on a mounting block, but also in combination with a nozzle holder on a magnetic foot.

| Designation | Article no. |

|---|---|

| Accelerator nozzle on mounting block | 90 30 01 03 01 |

| Acc. n. with integrated check valve on mounting block | 90 30 01 03 06 |

Round jet nozzle / Air jacket nozzle

Description:

Predestined to spray smallest amounts of your preferred medium. The air jacket surrounds the oil-containing spray-jet, leads it to its destination and protects it from outer influences e.g. environmental airflows. The result is an even more precise spray pattern as with the accelerator nozzle.

Preferred installation:

On mounting block. As well usable in combination with a magnetic nozzle holder.

Angled nozzle

Description:

A universally usable round-jet nozzle.

Preferred installation:

Specially designed for space-saving installation in casings. Installation in a casing bore diameter of about 13.5 (G ¼") by means of a fastening nut (bulkhead union).

| Designation | Article no. |

|---|---|

| 'Bulkhead' angled nozzle | 90 30 01 05 00 |

Flat jet nozzle

Description:

A universally usable flat jet nozzle for the planar surface wetting.

Preferred installation:

FFixed installation in plant and machinery in a G 1/8" bore and frequently also several parallel nozzles to extend the 'spray width'. Alternatively by means of a mounting block. Nozzle holder on a magnetic foot (30 001 50 01 or ... 02) for fast mounting/demounting or flexible adjustment of the spray direction.

| Designation | Article no. |

|---|---|

| Flat jet nozzle | 90 30 01 06 00 |

| Flat jet nozzle on mounting block | 90 30 01 06 01 |

| Flat jet nozzle V2A | a. A. |

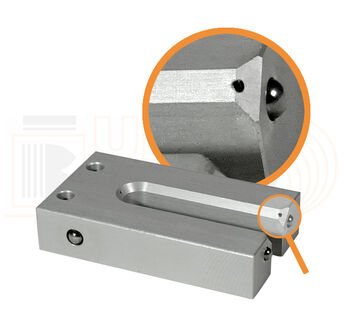

U-type nozzle

SKN

Description:

U-type nozzle for supplying coolants/lubricants preferably on vertical band saws and circular saws. The special arrangement of the nozzle bores ensures optimum supply of the cooling medium for the sawing process itself and for guidance of the saw band. In the case of the nozzle version for circular saws, the bore diameters of the U-type nozzle have been specially adapted to the specific requirements of this sawing process. SKN 55..75 nozzles are envisaged for particularly large saw blade diameters. At the request of the customer, all SKN nozzles are also available without bore no. 1.

Preferred installation:

Fixed installation in the system by means of fastening screws.

| Designation | Article no. | Ø Saw blade / Bandwidth |

|---|---|---|

| U-nozzle SKN 50 for circular saw | 90 30 01 20 50 KS | to Ø 450 |

| U-nozzle SKN 60 for circular saw | 90 30 01 20 60 KS | |

| U-nozzle SKN 70 circular saw | 90 30 01 20 70 KS | |

| U-nozzle SKN 55 circular saw LW 20 | 90 30 01 20 55 KS | up to Ø 450 |

| U-nozzle SKN 75 circular saw LW 20 | 90 03 01 20 75 KS | over Ø 450 |

| U-nozzle SKN 50 for vertical band saw | 90 30 01 20 50 BS | 18 - 27 |

| U-nozzle SKN 60 for vertical band saw | 90 30 01 20 60 BS | 27 - 34 |

| U-nozzle SKN 70 for vertical band saw | 90 30 01 20 70 BS | 34 - 41 |

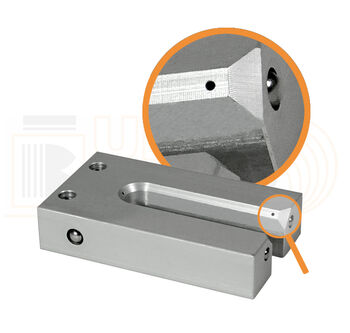

U-type nozzle

SKS

Description:

U-type nozzle for supplying coolants/lubricants preferably on vertical band saws and circular saws. The special arrangement of the nozzle bores ensures optimum supply of the cooling medium for the sawing process itself and for guidance of the saw band. In the case of the nozzle version for circular saws, the bore diameters of the U-type nozzle have been specially adapted to the specific requirements of this sawing process. SKN 55..75 nozzles are envisaged for particularly large saw blade diameters. At the request of the customer, all SKN nozzles are also available without bore no. 1.

Preferred installation:

Fixed installation in the system by means of fastening screws

| Designation | Article no. | Ø Saw blade / Bandwidth |

|---|---|---|

| U-type nozzle SKS 40 for horizontal band saw | 90 30 01 21 40 BS | 18 - 27 |

| U-type nozzle SKS 50 for horizontal band saw | 90 30 01 21 50 BS | 27 - 34 |

| U-type nozzle SKS 60 for horizontal band saw | 90 30 01 21 60 BS | 34 - 41 |

| U-type nozzle SKS 70 for horizontal band saw | 90 30 01 21 70 BS | 41 - 54 |

| U-type nozzle SKS 55 for band saw LW 20 | 90 30 01 21 55 BS | Ext. wide |

| U-type nozzle SKS 75 for band saw LW 20 | 90 30 01 21 75 BS | Ext. wide |

| U-type nozzle SKS 40 for band saw | a.A. | |

| U-type nozzle SKS 50 for band saw | a.A. | |

| U-type nozzle SKS 60 for band saw | a.A. | |

| U-type nozzle SKS 70 for band saw | a.A. |

Are you interested

in our nozzles?

If so, please arrange a consultation meeting now, with no obligation on your part. If you have any questions, our team will be pleased to assist you and explain all of the possible applications. Simply phone +49 7907 942 92 0, send an e-mail to info@unioeler.de or use the contact form.