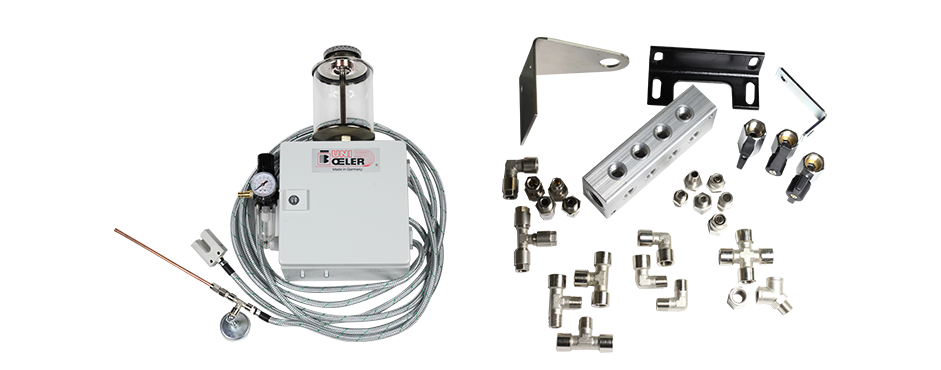

UNI Microspray II

minimum quantity cooling lubricating system

The Microspray II is also available without a foot switch as a system for integration into a machine control unit.

| Type | Article No. |

|---|---|

| Microspray II el. | 30 100 01 00 |

Technical specifications

Microspray II - electrically driven

| Tank size | 500 ml to 3000 ml |

|---|---|

| Operating voltage | 24V / 50 Hz / 24 VDC / 230 V 50 Hz / ask for alternative power supplies |

| Compressed air supply | Quick coupling (NW 7,2) 6 bar max. (3 bar min.) Factory settings: 4 bar |

| Dosing volume | Medium: (e.g. oil ) infinitely variable approx. 3 - 85 mm³/stroke | Air: infinitely variable |

| Hose length | Standard: 2,5 m (other lengths are possible) |

| Nozzle | Standard: Copper-nozzle on a magnetic foot (go to "Nozzles" for an alternative selection) |

UNI Microspray II Set

minimum quantity cooling lubricating system

The uncomplicated solution for retrofitting an effective minimum quantity cooling-lubricating system (MMKS) to your milling machine, lathe or pillar drill. This ready-to-connect SET, consisting of an oil tank, micro-dosing pump, spray nozzle and foot switch is simply attached to the machine with holding magnets and connected to a compressed air supply. The Microspray II combines the proven individual components of the Microspray I in a compact and variably usable unit that can be equipped with one or two dosing pumps.

| Type | Article No. |

|---|---|

| Microspray II SET | 30 100 00 00 |

Technical specifications

Microspray II Set - pneumatically driven

| Tank volume | 500 ml to 3000 ml |

|---|---|

| Compressed air supply | 6 bar max.; quick coupling (NW 7,2). Alternative: hose screw connection |

| Dosiervolumen | Medium: (e.g. oil ) infinitely variable approx. 5 - 100 mm³ | Air: infinitely variable |

| Hose length | Standard: 2,5 m (other lengths are possible) |

| Nozzle | Standard: Copper-nozzle on a magnetic foot (go to "Nozzles" for an alternative selection) |

Are you interested in our

UNI Microspray II?

If so, please arrange a consultation meeting now, with no obligation on your part. If you have any questions, our team will be pleased to assist you and explain all of the possible applications. Simply phone +49 7907 942 92 0, send an e-mail to info@unioeler.de or use the contact form.