Our spring-loaded oil cups

Areas of application

- Automotive industry

- Fibre and paper manufacturers

- Transport and aviation

- Textile industry

- Automatic car washes

- Timber industry

- Sewage treatment plants

- Tobacco processing

- Animal feed manufacturers

- Beverage industry

- Fertiliser manufacturers

- Mining

- Food manufacturers

- Oil production and refineries

- Dairies

- Chemical plants

- Printing companies

- Air-conditioning systems

- Ceramics industry

- Conveyor systems

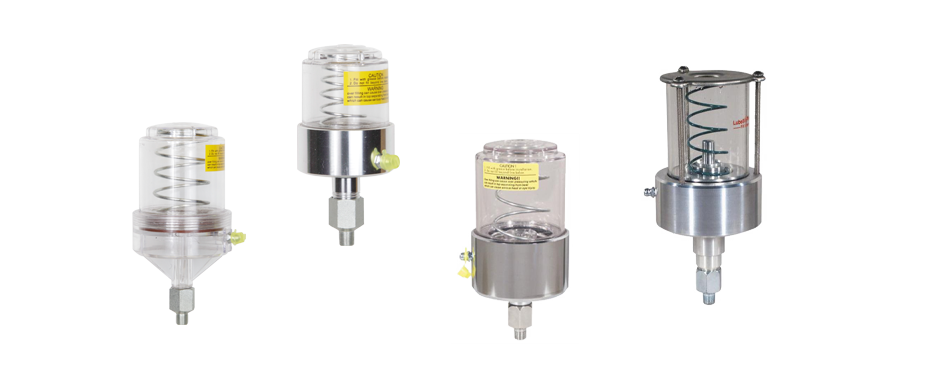

200 series

202, 205, and 260 in transparent casings are the standard grease dispensers for use on most bearing points. As they only deliver grease when the bearing is in operation, the bearing is equally protected from over-lubrication and dry running.

- The devices are supplied as standard with a 'medium' strength spring.

- Operating range: -25 to +120°C

Technical specifications for the 200 series

| Type | 202 | 205 | 260 |

|---|---|---|---|

| Capacity in g | 28 | 56 | 170 |

| Height in mm | 92 | 120 | 155 |

| ø in mm | 45 | 61 | 78 |

| Tank | Polycarbonate | ||

| Casing | Polycarbonate | ||

| Sealing | Neoprene | ||

Further notices

More informations considering topics like "Choose the right unit", "Choose the right spring-strength", "Lubricant dispensers installation instructions" and "Notes on lubricants" you can get further down on this page - or as well as PDF download.

300 series

302, 305, and 360 are specifically designed for use under high shock loads, vibration, and centrifugal forces. The strong metal casings compensate for these loads..

- main areas of application: eccentric presses, vibrators, stone grinders, construction machinery, pumps, etc.

- The devices are supplied as standard with a 'medium' strength spring.

- Operating range: -25 to +120°C

Technical specifications for series 300

| Type | 302 | 305 | 360 |

|---|---|---|---|

| Capacity in g | 28 | 56 | 170 |

| Height in mm | 89 | 120 | 152 |

| ø in mm | 45 | 61 | 76,2 |

| Tank | Polycarbonate | ||

| Casing | Aluminum, anodized | ||

| Sealing | Neoprene | ||

Further notices

More informations considering topics like "Choose the right unit", "Choose the right spring-strength", "Lubricant dispensers installation instructions" and "Notes on lubricants" you can get further down on this page - or as well as PDF download.

500 series

502, 505 and 560 also withstand chemically corrosive influences. The light-metal casings are nickel-chromium coated and the seals are made of chemical-resistant VITON.

- proven areas of application: chemical industry, food industry and nuclear technology

- The devices are supplied as standard with a 'medium' strength spring.

- Operating range: -25 to +120°C

Technical specifications for series 500

| Type | 502 | 505 | 560 |

|---|---|---|---|

| Capacity in g | 28 | 56 | 170 |

| Height in mm | 89 | 120 | 152 |

| ø in mm | 45 | 61 | 75 |

| Tank | Polycarbonate | ||

| Casing | Aluminum, NiCr-coated | ||

| Sealing | VITON | ||

Further notices

More informations considering topics like "Choose the right unit", "Choose the right spring-strength", "Lubricant dispensers installation instructions" and "Notes on lubricants" you can get further down on this page - or as well as PDF download.

Further notices

Choose the right unit

a) Size of the unit

The following four factors must be considered when selecting the size:

- Shaft diameter

- Whether the bearing is open or enclosed

- Peripheral speed of the shaft

- Whether interrupted or continuous running

LubeSite Type

| Shaft ø | to 40 mm | ||||

|---|---|---|---|---|---|

| Running time | interrupted | continuous | |||

| Bearing | open | closed | open | closed | |

| below 1000 rpm | 202, 302, 502 | 202, 302, 502 | 202, 302, 502 | 202, 302, 502 | |

| 1000 - 2500 rpm | 202, 302, 502 | 202, 302, 502 | 202, 302, 502 | 202, 302, 502 | |

| above 2500 rpm | 205, 305, 505 | 202, 302, 502 | 205, 305, 505 | 205, 305, 505 | |

| Shaft ø | 40 mm and above | ||||

| below 1000 rpm | 205, 305, 505 | 205, 305, 505 | 205, 305, 505 | 205, 305, 505 | |

| 1000 - 2500 rpm | 205, 305, 505 | 205, 305, 505 | 260, 360, 560 | 260, 360, 560 | |

| above 2500 rpm | 260, 360, 560 | 260, 360, 560 | 260, 360, 560 | 260, 360, 560 | |

Choose the right spring-strength

b) Spring strength

Each unit is equipped with a medium-strength spring because this spring strength is required for the majority of uses. In addition, weak and strong springs are supplied with each carton unit so that they are available when needed.

In order to determine which spring is necessary at what temperatures, it is necessary to know what lubricant is being used. The correct spring can then be determined with the aid of the following list:

Spring

| Operating temperature: | Lubricant consistency class | |||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | ||

| -23°C to +4°C | strong | medium | weak | - | - | |

| +5°C to +43°C | strong | medium | medium | strong | - | |

| +44°C to +93°C | - | weak | medium | medium | strong | |

| +94°C to +120°C | - | - | weak | medium | strong | |

| +121°C to +230°C | - | - | medium | medium | strong | |

Lubricant dispensers

c) Installation instructions

- Check the spring used:

Does the spring strength match to the selection table? - The lubricant dispenser is then screwed into the thread of the bearing.

Prior to installation because no air cushions are then created between the bearing and the lubricant dispenser. - The lubricant dispenser is then screwed into the thread of the bearing.

The dispenser's screw-in connector has an R 1/8" external thread. Appropriate adapter pieces may have to be fitted. - The lubricant dispenser can be installed in any position and operates interference-free, independently of its installation position.

Line paths of more than 30 cm in length should be avoided.

Notes on lubricants

As a matter of principle, discussions about lubricants should not take place and should be prevented if at all possible, because the lubricant used by the customer will have been recommended by the lubricant manufacturer.

However, you need to know a few basic points because they are directly related to the function of the oil/grease cup. The most important characteristic of lubricants is their consistency. Only lubricants should be used whose individual constituents do not separate, i.e. the NLGI group, consistency class 0-4 (low base oil fraction). NLGI - the globally recognized group classification by the National Lubricating Grease Institute of America.

Are you interested in our

spring-loaded oil cups?

If so, please arrange a consultation meeting now, with no obligation on your part. If you have any questions, our team will be pleased to assist you and explain all of the possible applications. Simply phone +49 7907 942 92 0, send an e-mail to info@unioeler.de or use the contact form.